Key Artisan - In the entertainment field, the term "Key Artisan" has come to represent an individual that can deal with any aspect of custom fabrication utilizing any materials to achieve the desired outcome for the client or project. Basically, if it has to be built, a key artist will be able to do it. One way or another.

Founding E.B. Effects and Design in 1989 and as the sole employee, it was necessary to become very proficient at all aspects of custom fabrication. The over 30 years of being a hands-on fabricator and designer has honed those skills to a fine edge making Phillip, still, very much a Key Artisan of E.B. Effects.

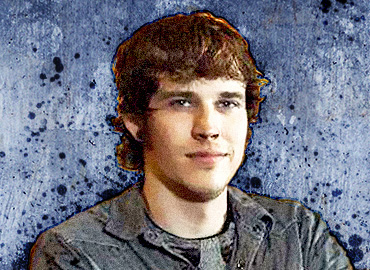

Literally growing up in the shop, Ty has learned every aspect of custom fabrication, mold-making, metal fabrication and precision assembly. A strong interest in all things automotive led him to a degree as a certified ASE Tech. His ability to adapt, design on-the-fly and problem solve has served him well working up through the ranks - as a helper, fabricator, shop lead, and finally securing his place as a Key Artisan.